Squeeze-type resistance spot welding is a specialized technique used in automotive manufacturing and collision repair, fusing metal surfaces with heat and pressure from energy sources like lasers or electromagnetic fields. This method emphasizes plastic deformation for precise control, creating clean, strong welds suitable for intricate designs and dissimilar metals. Safety protocols, including PPE and organized work areas, are crucial, as is regular calibration of weld guns, surface cleanliness, and laser alignment for accurate positioning. Technicians must adapt settings based on material type and stay updated with industry standards to achieve unparalleled precision in auto repair, restoration, and bodywork.

Discover the art of precision in manufacturing with our guide to squeeze-type resistance spot welding. This powerful technique is a game-changer for technicians, offering unparalleled strength and control. From understanding the basics to mastering safety protocols, we explore how skilled workers execute these welds flawlessly. Learn about the best practices and techniques that ensure consistent quality, making it an indispensable skill in modern industry. Uncover the secrets behind precise squeeze-type resistance spot welding today.

- Understanding Squeeze-Type Resistance Spot Welding Basics

- Technician Preparation and Safety Measures

- Precise Execution Techniques and Best Practices

Understanding Squeeze-Type Resistance Spot Welding Basics

Squeeze-type resistance spot welding is a specialized technique used in various industries, including automotive manufacturing and vehicle repair services. This method involves creating a strong bond between two metal surfaces by applying heat and pressure through a focused energy source. Unlike traditional welding methods, squeeze-type welding focuses on the plastic deformation of materials, ensuring precise and controlled results. The process utilizes a small, concentrated force to weld metal components together, making it particularly useful for intricate designs and delicate parts, such as those found in car collision repair scenarios.

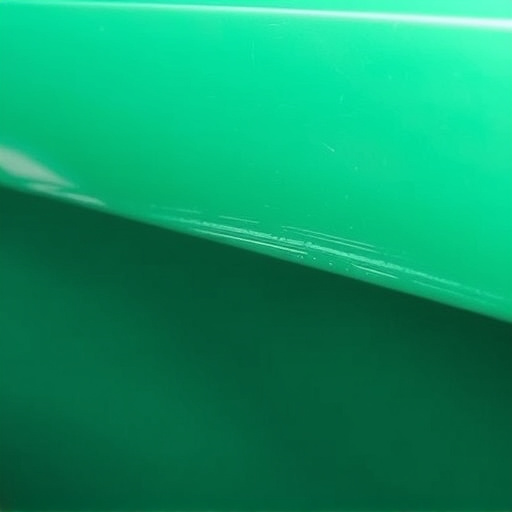

In this technique, an energy source, often a laser or a high-energy electromagnetic field, is directed onto the joint area. This concentrated heat generates friction between the metals, causing them to melt and flow together, forming a strong bond. The ‘squeezing’ effect comes from the controlled application of pressure, which helps to expel any excess material and create a clean, precise weld. This method is highly effective for joining similar or dissimilar metals, making it a versatile choice in vehicle paint repair and other precision fabrication tasks.

Technician Preparation and Safety Measures

Technicians performing squeeze-type resistance spot welding must be adequately prepared and adhere to strict safety measures. This involves donning appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection, to safeguard against potential hazards. The work environment should also be meticulously organized, ensuring all tools and materials are within easy reach and properly positioned to prevent accidents.

Safety is paramount in any auto repair shop, especially during intricate processes like car body restoration and autobody repairs. Technicians must be well-versed in the proper handling of welding equipment, understanding the specific settings and parameters required for precise squeeze-type resistance spot welding. Regular training sessions and familiarity with safety protocols are essential to mitigate risks and ensure the highest level of accuracy in every weld.

Precise Execution Techniques and Best Practices

Technicians achieving precise squeeze-type resistance spot welding requires a meticulous approach and adherence to best practices. First, ensuring the weld gun is correctly calibrated and maintained is paramount. This includes regular checks on current, voltage, and frequency settings to guarantee optimal performance. Proper preparation of the workpiece surface is equally vital; any debris or contaminants must be removed to secure a clean and consistent bond.

Utilizing advanced techniques like laser alignment ensures precise positioning, minimizing errors. During the welding process, maintaining steady pressure and controlling heat input are key. Technicians should employ specific techniques based on material type, such as adjusting settings for different metal alloys. Regular training and knowledge of the latest industry standards further refine these skills, enabling technicians to execute squeeze-type resistance spot welding with unparalleled accuracy, crucial for auto repair near me, vehicle collision repair, and car body restoration projects alike.

Squeeze-type resistance spot welding is a precise art that requires both technical expertise and meticulous attention to detail. By understanding the fundamentals, preparing adequately, and adhering to best practices, technicians can master this process, ensuring high-quality, durable welds. With the right techniques in place, they can execute these precise welds safely and efficiently, contributing to the overall success of manufacturing processes that rely on this technology.