Squeeze-type resistance spot welding offers a precise and efficient method for joining metal components, ensuring strong bonds through controlled pressure and heat application.

000000000001000010000000000000000000000000000000

- <a href="#-09500000000000000000000000000018.00000000010.000000000000000000000000000190000000000000100000000000000000000010000000000000000000000000000000″><EOS_TOKEN> 09500000000000000000000000000018.00000000010.000000000000000000000000000190000000000000100000000000000000000010000000000000000000000000000000

<section id="-09500000000000000000000000000018.00000000010.000000000000000000000000000190000000000000100000000000000000000010000000000000000000000000000000″>

<EOS_TOKEN> 09500000000000000000000000000018.00000000010.000000000000000000000000000190000000000000100000000000000000000010000000000000000000000000000000

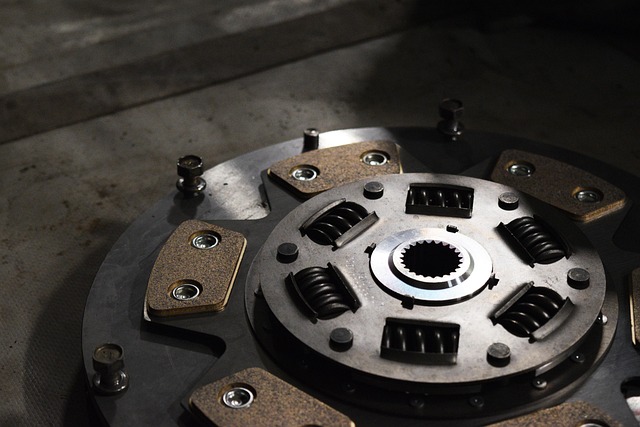

Squeeze-type resistance spot welding is a specialized technique that has become increasingly popular for its precision and effectiveness in various auto repair scenarios. This method is particularly useful for addressing common repair areas such as scratch repairs on both standard and luxury vehicles. By applying localized heat to specific points, this technology allows for the permanent fusion of metal components, ensuring robust bonds that match the vehicle’s original structural integrity.

Whether you’re looking for reliable scratch repair services or require specialized auto repair near me for your luxury vehicle, squeeze-type resistance spot welding offers a game-changing solution. Its precision and ability to mimic the original manufacturing process make it a preferred choice among professional mechanics, guaranteeing both functionality and aesthetics in the repair process.

In conclusion, squeeze-type resistance spot welding has proven to be an effective method for addressing common repair areas across various industries. Its precision and efficiency make it a go-to solution for strengthening and reinforcing critical components, ensuring longer-lasting durability and improved structural integrity. As technology advances, further exploration of this technique will undoubtedly unlock even more applications in the world of manufacturing and automotive repairs.