Squeeze-type resistance spot welding is an advanced, precise repair technique renowned for creating strong, durable bonds between metal surfaces. In auto body restoration, it excels at dented panel repairs while preserving structural integrity and original aesthetics, making it a game-changer in the automotive industry. This versatile method minimizes material removal, enhances efficiency, reduces waste, and cuts turnaround times across diverse industries like manufacturing, machinery, electronics, and aerospace, earning its reputation as a top choice for factory-grade repairs.

“Discover why squeeze-type resistance spot welding is the go-to method for factory-grade repairs. This powerful technique offers unparalleled precision, making it ideal for demanding automotive and aerospace applications. Unlike traditional welding methods, spot welding ensures strong, reliable bonds with minimal heat input and material distortion. Read on to explore the advantages, from reduced production time to consistent quality, and understand why this process is revolutionizing repair practices across industries.”

- Understanding Squeeze-Type Resistance Spot Welding: A Powerful Repair Technique

- Advantages of Using Resistance Spot Welding for Factory-Grade Repairs

- Applications and Industries Benefiting from This Precision Welding Method

Understanding Squeeze-Type Resistance Spot Welding: A Powerful Repair Technique

Squeeze-type resistance spot welding is a highly effective and precise technique that has earned its place as a preferred method for factory-grade repairs. This advanced process involves applying focused pressure and electrical energy to create a robust bond between two metal surfaces. By controlling the amount of heat and pressure, this method ensures deep penetration, resulting in a strong and durable weld.

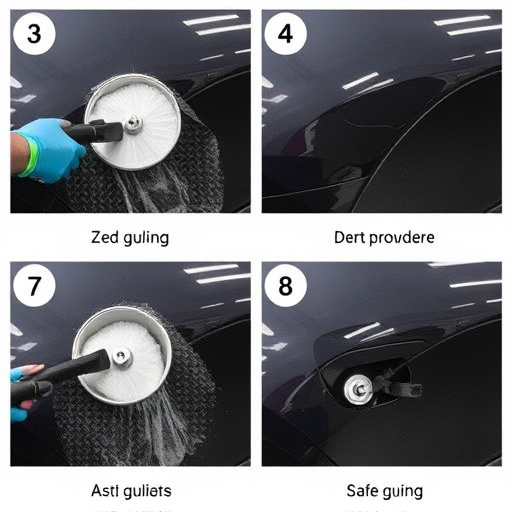

In the context of auto body restoration and fender repair, squeeze-type resistance spot welding offers significant advantages. It allows for the precise repair of dented panels and damaged components without compromising structural integrity. This non-destructive technique is also ideal for auto dent repair, preserving the original vehicle aesthetics while ensuring the safety and strength of the repaired areas, making it a game-changer in the automotive restoration industry.

Advantages of Using Resistance Spot Welding for Factory-Grade Repairs

Resistance Spot Welding (RSW), particularly using a squeeze-type resistance spot welding process, offers numerous advantages for factory-grade repairs across various industries, including automotive and auto detailing sectors. This advanced welding technique ensures precise and robust connections, making it ideal for high-quality, structural repair work in cars, and other vehicles. RSW allows for the repair of complex geometries and thin materials without compromising on strength or integrity, a critical factor in ensuring vehicle safety and performance during auto dent repairs and car paint repairs.

Moreover, squeeze-type resistance spot welding is known for its consistency and repeatability, enabling technicians to achieve reliable and uniform welds every time. This precision minimizes the need for excessive material removal and subsequent auto detailing work, which can be both costly and time-consuming. By preserving the original vehicle structure, RSW contributes to reduced waste and faster turnaround times, ultimately enhancing efficiency in modern manufacturing and repair facilities.

Applications and Industries Benefiting from This Precision Welding Method

Resistance spot welding, specifically the squeeze-type resistance spot welding technique, has a wide range of applications and is favored across various industries for precise and high-quality repairs. Its ability to create strong, durable bonds makes it an ideal choice for automotive body shops dealing with car collision repair and dent removal. This method ensures minimal heat input, allowing for the preservation of sensitive materials and their structural integrity.

Beyond the automotive sector, resistance spot welding is also used in manufacturing industries where precision and efficiency are paramount. It enables the repair or assembly of intricate metal components found in machinery, electronics, and even aerospace applications. The versatility of this technique, combined with its ability to produce consistent and reliable welds, makes it a preferred choice for achieving factory-grade repairs across diverse industries.

Squeeze-type resistance spot welding stands out as a preferred method for factory-grade repairs due to its precision, efficiency, and robust bond strength. Its ability to join similar and dissimilar metals makes it versatile across various industries, from automotive to aerospace. The advantages discussed in this article highlight why this technique is not just a game-changer but an indispensable tool for ensuring structural integrity and quality control in manufacturing settings.