Squeeze-type resistance spot welding is a precise and powerful factory-grade repair technique for diverse industries, especially automotive collision repairs. It combines pressure and heat to create strong, permanent bonds with meticulous control over weld size and depth, minimizing material distortion and producing high-quality welds in seconds. Ideal for complex vehicle body repair scenarios requiring adherence to original factory specs and high-volume production lines.

In the realm of factory-grade repairs, Resistance Spot Welding (RSW) stands out as a preferred method due to its precision and durability. This article delves into the intricacies of RSW, focusing on the benefits of squeeze-type resistance spot welding techniques. We explore how this advanced process enhances application versatility, ensuring repairs that match the longevity of original components. By understanding RSW, particularly its squeeze-type variant, professionals can make informed choices for superior structural integrity.

- Understanding Resistance Spot Welding: A Factory Repair Method

- Advantages of Squeeze-Type Resistance Spot Welding Techniques

- Applications and Impact in Ensuring Longevity of Repairs

Understanding Resistance Spot Welding: A Factory Repair Method

Resistance spot welding, specifically the squeeze-type resistance spot welding method, is a precise and powerful technique that has become a go-to for factory-grade repairs across various industries, particularly in automotive sectors like car collision repair and vehicle body repair at auto collision centers. This process involves using a specialized machine to generate heat through electrical resistance within the metal being welded, creating a strong and permanent bond.

The method’s accuracy allows for precise control over weld size and depth, ensuring structural integrity without excess material removal or addition. This precision is especially beneficial in complex vehicle body repair scenarios where maintaining original factory specifications is crucial. Squeeze-type resistance spot welding also offers consistent results, making it ideal for high-volume production lines where quality and uniformity are paramount.

Advantages of Squeeze-Type Resistance Spot Welding Techniques

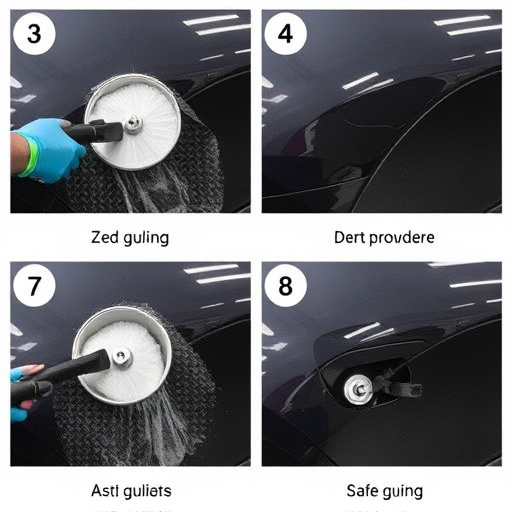

Squeeze-type resistance spot welding is a highly efficient technique that offers several advantages for factory-grade repairs in the automotive industry. This process involves applying pressure and heat to create a strong, durable weld between two metal surfaces. One of its key benefits is precision; it allows for accurate control over weld size and depth, ensuring minimal penetration into the base material and maximizing the strength at the weld joint. This level of precision is crucial when dealing with delicate components or maintaining structural integrity in auto collision repair and dent removal processes.

Furthermore, squeeze-type resistance spot welding is known for its speed and efficiency. The technique can produce high-quality welds in a matter of seconds, making it ideal for assembly lines where quick turnaround times are essential. This process also generates minimal heat affected zone (HAZ), reducing the risk of material distortion or degradation commonly seen in other welding methods, especially when conducting auto glass replacement or complex panel repairs.

Applications and Impact in Ensuring Longevity of Repairs

In the realm of factory-grade repairs, especially for vehicles like cars, fenders, and other components within collision repair services, squeeze-type resistance spot welding stands out as a preferred method. Its applications are vast and impact the longevity of these repairs significantly. This precise technique allows for localized heating and cooling, ensuring minimal distortion in the surrounding areas while creating strong bonds.

The process is particularly beneficial for intricate geometries and tight spaces, where other welding methods might struggle to maintain precision. The result is not just a stronger repair but also a more aesthetically pleasing one, preserving the original form and finish of the damaged part. This level of detail is crucial in car body repair, ensuring that vehicles return to their pre-incident condition or even surpass it in terms of structural integrity and visual appeal.

Resistance spot welding, particularly the squeeze-type method, stands out as a preferred choice for factory-grade repairs due to its numerous advantages. This technique offers enhanced precision, faster cycle times, and superior joint strength, ensuring that repairs match the original manufacturing quality. By leveraging squeeze-type resistance spot welding, manufacturers can achieve long-lasting and robust bonds, ultimately improving the overall durability and performance of assembled components.