Squeeze-type resistance spot welding is a specialized process vital for maintaining structural integrity in automotive applications, especially car dent repair and collision scenarios. It uses precise pressure and heat to create high-strength welds that enhance vehicle safety features like airbag deployment systems. This method ensures the reliability of welded joints in extreme conditions, making it indispensable in modern car repair shops for restoring vehicles to pre-collision condition with intact safety features.

“Resistance Spot Welding (RSW), particularly its squeeze-type variant, plays a critical role in ensuring the integrity of airbag deployment and sensor functionality in modern vehicles. This precise welding technique fuses components together with minimal distortion, enhancing structural stability. By integrating sensors seamlessly into the weld, RSW optimizes airbag performance and safety. The article delves into the intricacies of squeeze-type RSW, its applications in airbag systems, and how it maintains function integrity, ultimately contributing to enhanced vehicle security.”

- Understanding Squeeze-Type Resistance Spot Welding

- Airbag Deployment and Sensor Integration

- Ensuring Function Integrity Through Precise Welding Techniques

Understanding Squeeze-Type Resistance Spot Welding

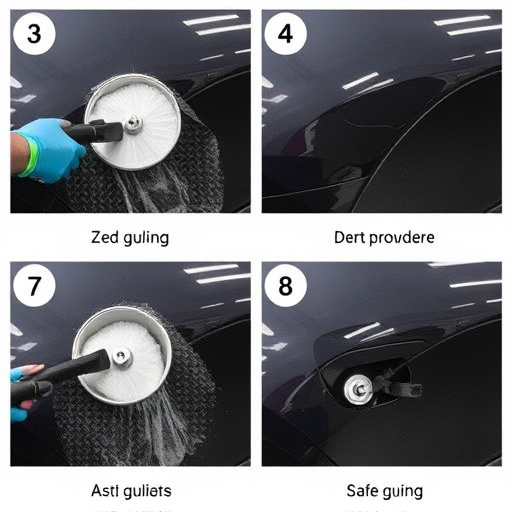

Squeeze-type resistance spot welding is a specialized process that plays a critical role in ensuring the structural integrity of components in automotive applications, particularly in car dent repair and vehicle collision repair scenarios. This technique involves applying precise pressure and heat to create a strong bond between metal sheets. The process utilizes a concentrated force, often delivered through a cylindrical tool, to deform the metal surfaces, resulting in a robust weld that can withstand significant forces.

In the context of airbag deployment systems and sensor functionality, squeeze-type resistance spot welding guarantees that the welded joints remain intact during extreme conditions. This is vital for vehicle safety, as it prevents any structural failure that might compromise the effectiveness of airbags or sensors during a collision. The ability to achieve consistent and high-strength welds makes this method indispensable in modern car repair shops, ensuring that vehicles return to their pre-collision condition with enhanced safety features intact.

Airbag Deployment and Sensor Integration

Airbag deployment is a critical safety feature in modern vehicles, designed to protect occupants during a collision. The process involves a series of precise events, including sensor activation and rapid inflation. Squeeze-type resistance spot welding plays a vital role here by ensuring the structural integrity of components that house these sensors. This advanced welding technique creates robust bonds, enhancing the overall strength of the automotive body work.

In an auto repair service or automotive repair service setting, the integration of sensors is a delicate process. These sensors are responsible for detecting impact and triggering the airbag system. Proper squeeze-type resistance spot welding guarantees that these sensors remain securely in place, even under extreme conditions. This ensures their functionality, which is paramount to saving lives and mitigating injuries during accidents.

Ensuring Function Integrity Through Precise Welding Techniques

In the automotive industry, ensuring function integrity of critical components like airbags and sensors is paramount for safety and performance. Squeeze-type resistance spot welding plays a pivotal role in achieving this by offering precise and robust connections. This advanced technique deposits a small amount of heat locally, minimizing heat affect on surrounding areas, which is crucial when working with sensitive electronic parts and materials used in modern vehicles.

By controlling variables such as current, time, and pressure, squeeze-type resistance spot welding guarantees the structural and electrical integrity of welds. This precision ensures that airbag deployment mechanisms function flawlessly during collisions, and sensors remain reliable, providing accurate data for advanced driver assistance systems (ADAS). Moreover, its effectiveness in bumper repair, automotive restoration, and car dent repair underscores its versatility and importance in maintaining the overall functionality and safety of vehicles.

Squarely addressing the need for robust and reliable connections in automotive safety systems, squeeze-type resistance spot welding emerges as a pivotal technology. By ensuring meticulous weld integrity, this technique maintains the critical function of airbags and sensors, ultimately contributing to enhanced passenger protection. Through precise control of pressure, energy, and timing, squeeze-type resistance spot welding creates indelible bonds, fortifying the intricate interplay between these life-saving mechanisms.